Asbestos has been around for centuries. Still, it was only in the 20th century that it became common in nearly every industry in the United States. It was present in thousands of products and widely used by all branches of the U.S. military. Many occupations are at risk for asbestos exposure.

Studies have shown that asbestos exposure is the No. 1 cause of work-related deaths worldwide, and about 1.3 million U.S. workers are potentially at risk of asbestos exposure at their place of employment.

What Makes Asbestos Dangerous?

The very properties that made asbestos the “miracle mineral” also made it deadly. Asbestos is naturally fireproof, making it indispensable to many industries, including the automobile, construction, manufacturing, power, chemical, and military industries. Manufacturers used asbestos under the guise of creating protective products and bolstering materials, but they knew early on that asbestos had harmful side effects.

Asbestos is comprised of six naturally occurring fibrous minerals. These tiny fibers are incredibly flexible, resistant to heat, electricity, and corrosion, and are virtually indestructible, making them incredibly useful in many different products. Construction materials used asbestos for their insulating properties, while cloth, paper, cement, plastic, and other materials used asbestos because it made them stronger.

How Were You Exposed to Asbestos?

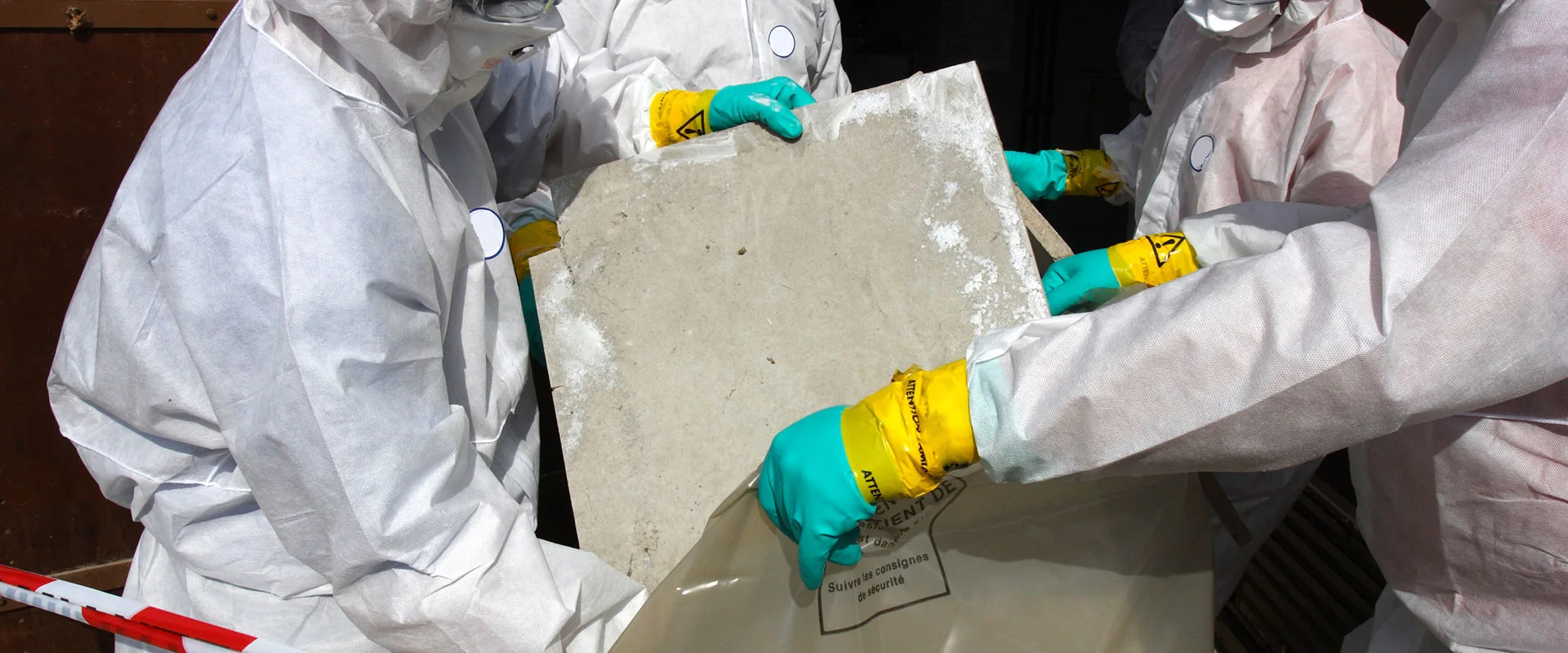

Because asbestos fibers are so small, they are easily dispersed in the air when disrupted. When construction materials are cut or destroyed, the small fibers enter the surrounding air, are breathed in by workers, and then lodge in the lungs, often leading to long-term health problems.

Jobs at Risk of Occupational Asbestos Exposure

From the 1920s to the 1980s, asbestos was present in thousands of products and job sites. The full list of occupations that were potentially exposed to asbestos is alarming.

Some of the most common examples of high-and-medium-risk asbestos-exposure jobs include:

Asbestos was present in aircraft parts due to its fire and friction resistance. Parts include brakes, brake pads, engine components (gaskets, valves, refractory fiber felt, tapes, cockpit heating systems), and many others. Workers were exposed when repairing and removing parts that shed asbestos and entered the air around them.

Many car parts were made with asbestos in a bid to make them last longer. Parts include:

- Insulation (floor, firewall)

- Mufflers

- Soundproofing

- Undercoating

- Brakes

- AC Housing

- Spark Plugs

- Clutches

- Valves

- Brakes (pads, shoes, and lining)

- Body filler compound

- And many more

Many mechanics came into contact with these products regularly. Additionally, the plants that manufactured the parts risked exposure.

No profession saw more asbestos exposure than boilermakers. Their entire workspace was covered with asbestos, including their tools, equipment, and clothing.

Boilermakers worked with high-pressure, steam-generating machines. All steam-generating types of equipment require the use of a boiler or hot water tank as their main energy-generating core. Because boilers emit incredibly high temperatures, asbestos was a perfect fit because it was fireproof, didn’t transfer heat, and provided insulation.

Materials containing asbestos include:

- Pipe connection adhesives

- Boiler tank liners

- Outer wraps on boiler tanks

- Floor, wall, and ceiling protection in boiler rooms

- Gaskets

- Insulative pipe wraps

- Bearings and rollers

- Cement for base pads, supports, and acoustic management

Pre-1990, nearly every brick and mortar compound contained asbestos to make them lighter and stronger. As bricklayers cut bricks to size, removed damaged ones, and mixed dry mortar, asbestos fibers entered their breathing space. Beyond that, asbestos was also present in the drywall, plumbing, electrical, roofing, and paint – all tools of the bricklayer trade that they handled and breathed in daily.

Carpenters are often involved in the renovation and remodeling of buildings and homes. The buildings they are working in are often older and were built when asbestos was commonly used. As carpenters are cutting away old drywall and insulation and removing flooring and ceiling tiles, they are likely interacting with asbestos that was added to make the building fireproof and soundproof.

Many of the tools and building products used by carpenters contained asbestos. Examples include drywall, insulation, plaster, pipes, and roofing materials. Additionally, many carpenters worked on construction sites where asbestos-containing products were common.

Carpenters regularly dealt with asbestos-containing materials, including:

- Adhesives

- Asbestos cement

- Asbestos lumber

- Asbestos boards, sheets, and panels

- Caulk and putty

- Ceiling tiles

- Drywall

- Felt

- Insulation

- Joint compound

- Paint

- Pipes

- Roofing materials

- Siding

- Vinyl flooring

Cement masons were exposed to asbestos in a variety of ways. They were often responsible for stirring asbestos into the cement mixture, then cast it into blocks, and service the machines used to create the blocks and mix the cement. The direct exposure to raw asbestos was incredibly harmful to their health.

Some of the products cement masons have manufactured or produced containing asbestos include:

- Blocks

- Compounds, sealants, and adhesives

- Concrete

- Countertops

- Furnace cements

- Gutters

- Masonry

- Panels and boards

- Pipes and coverings

- Cement sheets

- Shingles and siding

- Stove cement

- Tiles

Asbestos was highly used and present in electric equipment due to its heat and fire resistance. Electricians performed maintenance on equipment that may have contained asbestos, especially when removing insulation around old wiring or breaker boxes.

Equipment and materials containing asbestos include:

- Electrical ducts

- Circuit breakers

- Electrical wiring insulation

- HVAC units

- Cable wraps

- Turbines

- Generators

- Electrical shielding

- Electrical paper

- Heating units

- Hot water tanks.

Elevator workers saw an increased exposure to asbestos as the brake shoes on elevators were most often produced using asbestos. The repair of worn elevator parts exposed the workers as they cut, demolished, polished, and repaired elevator brake shoes and panel equipment.

Older buildings and schools that catch fire are often an asbestos hazard. As the building burns and falls apart, asbestos fibers are launched into the air. As firefighters arrive to control the fire, they are exposed to the asbestos fibers in the air. They are often unaware of the danger, and because of this, they are twice as likely to develop mesothelioma than the general public.

Firefighters are also at risk of toxic chemicals from firefighting foam. The chemical contained in the foam is linked to many different types of cancer.

Insulators work in many fields and are responsible for maintaining, replacing, and installing insulating material to regulate and control temperatures in buildings. Between the 1930s and 1970s, toxic asbestos was used in nearly every insulation product due to its ability to retain temperature, fireproofing, and resistance to corrosion.

Asbestos and vermiculite insulation was used in homes, buildings, ships, cars, manufacturing facilities, and anything that required insulation. The exposure risk was catastrophic for workers.

The insulation products associated with asbestos exposure include:

- Zonolite insulation

- Pipe insulation

- Block insulation

- Spray-applied insulation

- Valve insulation jackets

OSHA ranks construction as one of the most hazardous industries in the U.S. Construction workers deal with all types of materials during a build, especially because many materials were produced with asbestos for their fireproofing properties. Asbestos dust on construction sites exposed many workers quickly as the fibers clung to clothes, hair, and tools; it also traveled home with the workers, potentially exposing families to secondary exposure.

Trades at risk include:

- Bricklayers and masonry workers

- Carpenters

- Crane operators

- Demolition crews

- Drywall hangers

- Renovators

- Insulators

- Laborers

- Pipefitters

- Plasterers

- Plumbers

- Roofers

Laborers and factory workers were exposed to asbestos more than most trades and have a much higher rate of developing asbestos-related diseases than the general public.

The most common type of exposure happened when general laborers were transporting and handling raw asbestos fibers to manufacture products and parts. Exposure also occurred during demolition.

Laborers include:

- Maintenance crews

- Machine operators

- Drill press operators

- Equipment mechanics

- Assembly workers

- Machinists

Some of the products associated with asbestos include:

- Machine parts

- Construction materials

- Raw asbestos fibers

It is important to note that asbestos was so pervasive in factories and manufacturing plants that office workers, managers, and warehouse workers were also potentially exposed. Family members of laborers are also at risk as workers came home covered in asbestos fibers.

Many maintenance workers faced the same danger as construction workers as they saw the same risk factors. The buildings they worked in and their equipment contained asbestos, especially older buildings and schools built in the asbestos heyday.

Metal workers are in a profession that usually involves intense fire and heat, which is why asbestos was heavily used in this industry. Work areas and protective clothing were often covered in asbestos, putting workers at an increased risk of exposure. Metal workers were exposed as they cut, designed, and welded asbestos-containing metal and other parts. The types of products that posed a risk include coatings, construction materials, hot top insulation, metal products, and safety gear.

Metal workers include:

- Welders

- Forge men

- Foundry workers

- Iron workers

- Blacksmiths

- Sheet metal workers

- Structural metal craftsmen

- Tinsmiths

- Smelters

- Metal Lathers

- And more

The men and women of the armed forces put their lives on the line daily protecting our country and freedom. They lived on bases, drove vehicles, and used equipment laden with asbestos and asbestos-containing materials. The people with the highest risk of exposure were those that worked construction or performed maintenance jobs during their service. Those that worked in shipyards were especially vulnerable as the ships and parts contained a large volume of asbestos-based parts.

Learn more about how veterans were exposed to asbestos.

Workers in plants and factories where asbestos products were manufactured were often exposed to asbestos regularly. There was likely a higher concentration of asbestos fibers in the air, increasing their daily risk of exposure.

Locations and plants include steel mills, cement plants, textile mills, and many other plants or factories.

Painters were exposed as they sprayed asbestos-contained spackling compounds on walls and surfaces before they painted them. Many paint and textured coating compounds (i.e. popcorn ceilings) contained asbestos as well. Painters are ranked as one of the top five trades with the most exposure to toxic and hazardous chemicals.

Plumbing parts were often covered in asbestos because of their resistance to heat and corrosion; the insulation of pipes, tanks, ducts, and other parts was often made with asbestos for their fire and heat-resistant properties. Plumbers come into constant contact with pipes as they cut and drill them to fit the building or home they are working on. This activity disrupts the asbestos fibers, launching them into the breathable air. Plumbers who worked in the industry prior to 1980 have a higher risk of developing mesothelioma or lung cancer due to asbestos exposure.

Plumbing products that contain or contained asbestos include:

- Cement

- Heat Shields

- Insulation

- Joint compounds

- Pumps, valves, gaskets

- Welding rods

Railroad workers suffered higher rates of mesothelioma because their asbestos exposure was near constant as locomotives used asbestos-containing insulation, brakes, cement, and gaskets. Even railroad workers who did not handle repairs or construction were exposed because asbestos was so widely used. It was routine for workers to cut, sand, or smooth asbestos-containing materials – they often went home covered in asbestos fibers as dust was prevalent all over their work environment.

Asbestos was present in cabins and carriages, including floor tiles, wallboards, insulation, pipes, and cement. Conductors, yardmasters, workers, and even passengers were exposed to asbestos daily.

Railroad products containing asbestos include:

- Boilers

- Brakes and clutches

- Ceiling and floor tiles

- Cement ties

- Ash trays and coasters

- Gaskets

- Insulation

- Plaster

- Paint

- Sealing cement

- Wallboards

Asbestos was integral to roofing materials because it is lightweight, fireproof, extremely durable, inexpensive, and insulating. It was incorporated into roofing materials to ostensibly make them safer, contrary to the harmful health effects. While newer products should be asbestos-free, roofers dealing with older homes and buildings are still at risk for exposure.

Roofing materials containing asbestos fall into two categories:

- Friable: this type of material breaks apart easily and is more likely to be airborne.

- Non-Friable: These types of materials are more stable, but if damaged during demolition or due to excessive wear or bad weather, the asbestos fibers can still become airborne.

Examples of friable roofing materials include:

- Niccolite (often associated with wood shingles)

- Pipe insulation

- Roof paper

- Silver roof paint

- Sprayed insulation

Examples of non-friable roofing materials include:

- Caulking

- CAV or transite

- Cement roofing and paneling

- Felt paper

- Mastics

- Patch compounds

Roofers work with a variety of materials outside shingles. Some asbestos-containing products roofers will work with include:

- Asphalt shingles

- Mastic

- Binding materials

- Insulation

- Sealants

- Soundproofing materials

Roughly 30% of all mesothelioma lawsuits are filed on behalf of Navy veterans and shipyard workers. The demolition and repair in shipyards exposed workers as they handled old materials, repaired ships, and demolished decommissioned vessels.

Asbestos was common in steel mills because of its heat and corrosion-resistant properties. It also controlled the high temperatures required to work with steel. A study revealed that steelworkers were three times more likely to be diagnosed with mesothelioma than the general public.

Old school buildings are finding more and more asbestos in their walls. As schools around the nation make renovations and start falling apart, asbestos is found in the pipes, insulation, ceiling, floors, and walls. The EPA estimates that there are asbestos-containing materials in nearly every primary, secondary, and charter school building in the U.S.

Asbestos can be found in schools in the following places:

- Cement sheets

- Drywall

- Ceiling tiles

- Wallboard

- Textured paint

- Popcorn ceilings

- Vinyl flooring

- Duct work

- Pipe wrap insulation

- Boilers

Learn more about asbestos in our schools.

Vogelzang Law is Here to Help

If you have been diagnosed with lung cancer due to asbestos exposure, our team of experienced litigators is standing by. We hope you never have to call us, but if you do, know you have a relentless team of fighters standing by, protecting you from the storm and offering safe harbor.

Contact us for your free consultation – we’re here if you need us.